3D Printer cold pull using PLA

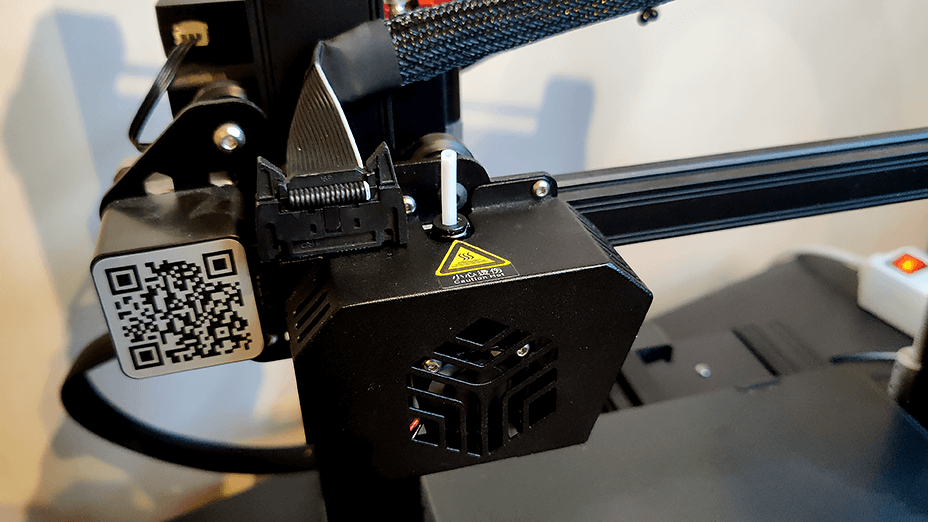

How to do 3D Printer cold pull using PLA. This is little bit different method because i am using small PTFE tube with PLA to do the cold pull. The reason why i keep small piece of PTFE tube in hotend is that it helps me to get PLA straight to the nozzle. It's more common way to remove PTFE tube with push fit/bowden and then use nylon filament for cold pull. The difference between doing cold pull with PLA or nylon filament is that nylon doesn't break as easily when pulling. Printer that i am using in this article is Creality CR-6 SE with Community Firmware Marlin.

If you have really bad clog on your hotend check this article: 3D Printer hotend clog removal

What do i need?

- Acupuncture/nozzle cleaning -needle. (Optional)

- New PTFE tube or you can also use your already attached PTFE tube.

- PLA filament.

Let's start!

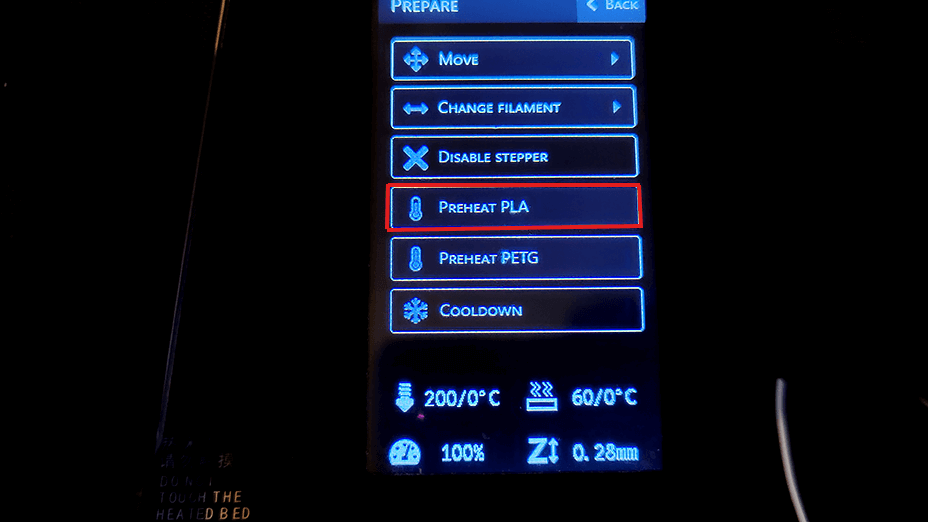

1. First preheat your printer.

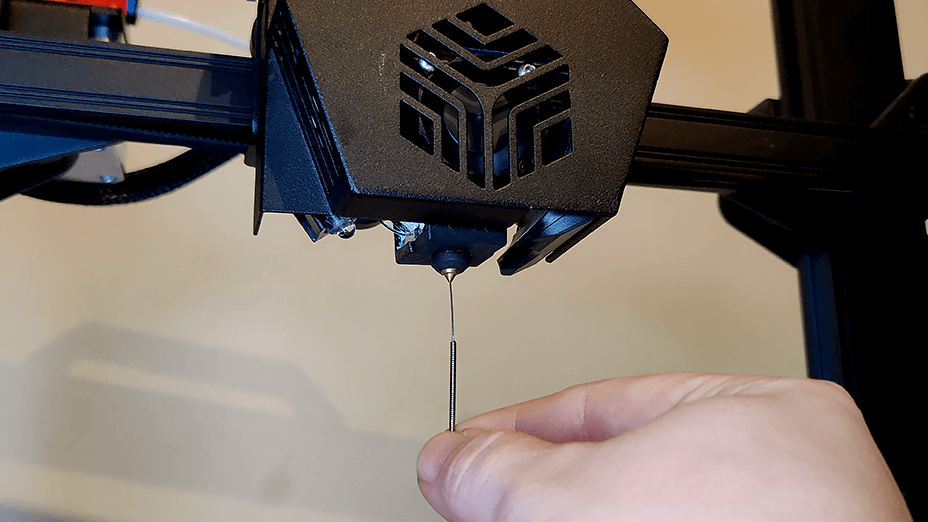

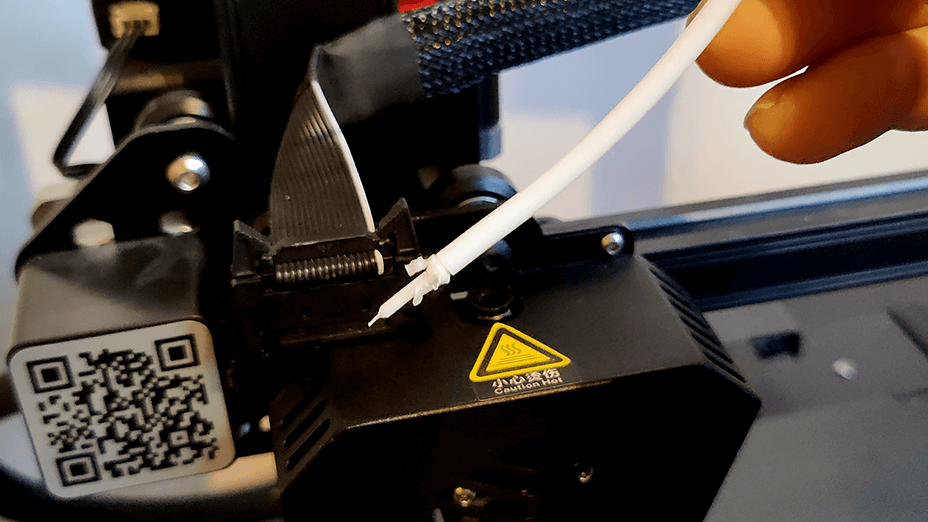

2. When the hotend is heated, use acupuncture/nozzle cleaning -needle if you have one. It will remove anything that is hard-stuck in your nozzle.

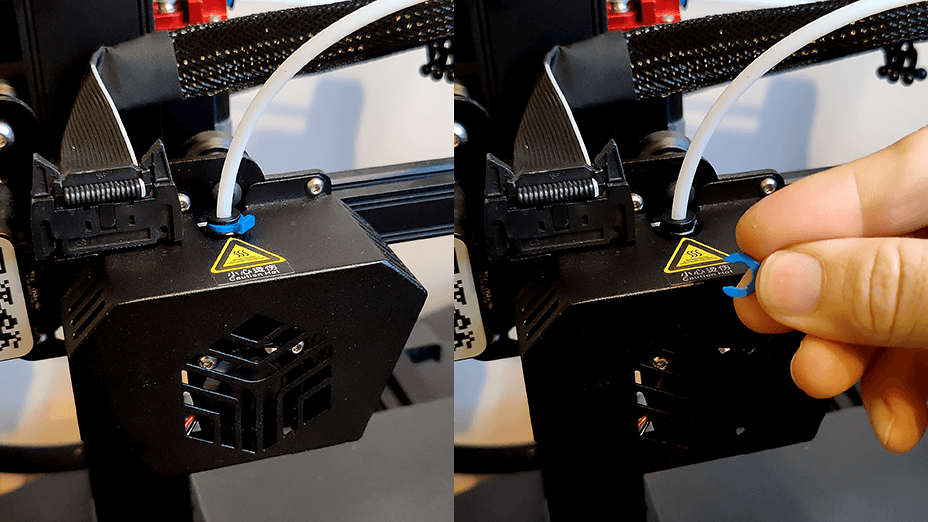

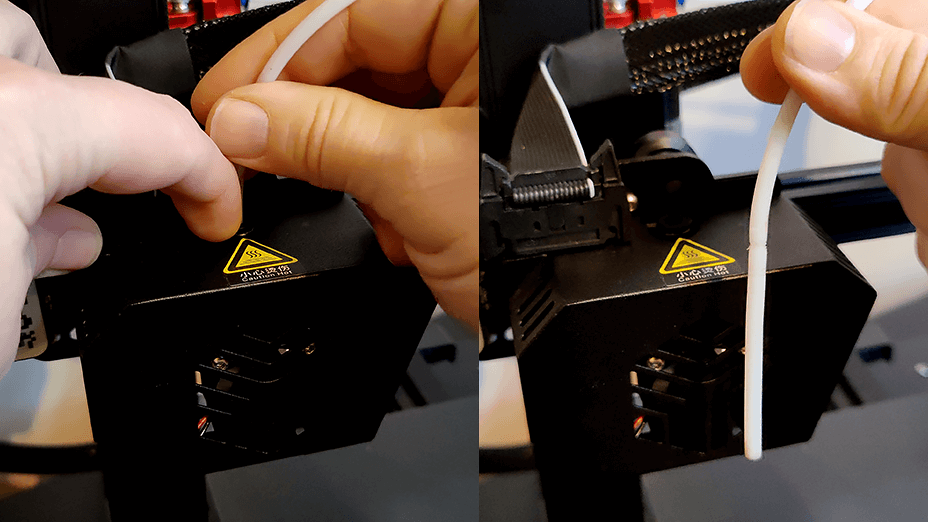

3. Remove collect clip from the push fit/bowden coupler.

4. Use your finger to push down push fit and pull PTFE tube out.

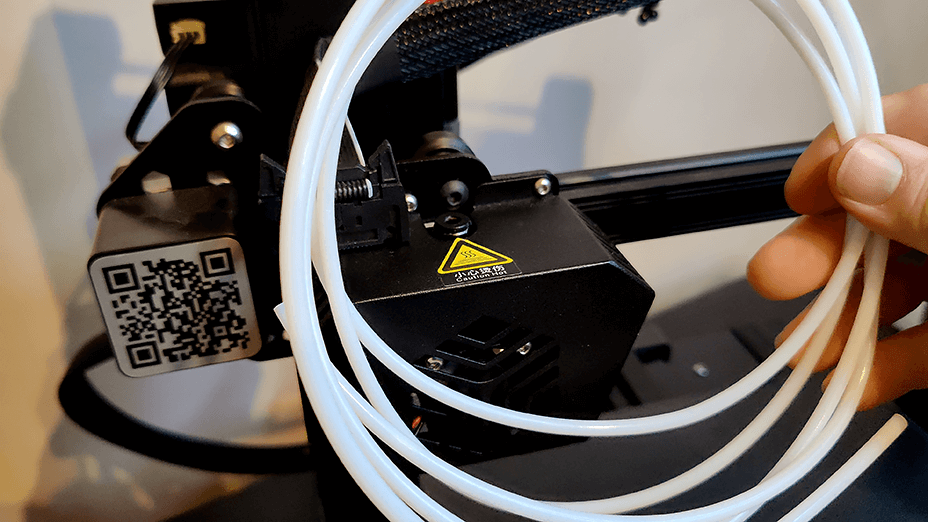

5. I have roll of new PTFE tube, and i'm using it to create small tube for cleaning purposes.

6. Put in the tube so that you can estimate where to cut.

7. And cut it to short length.

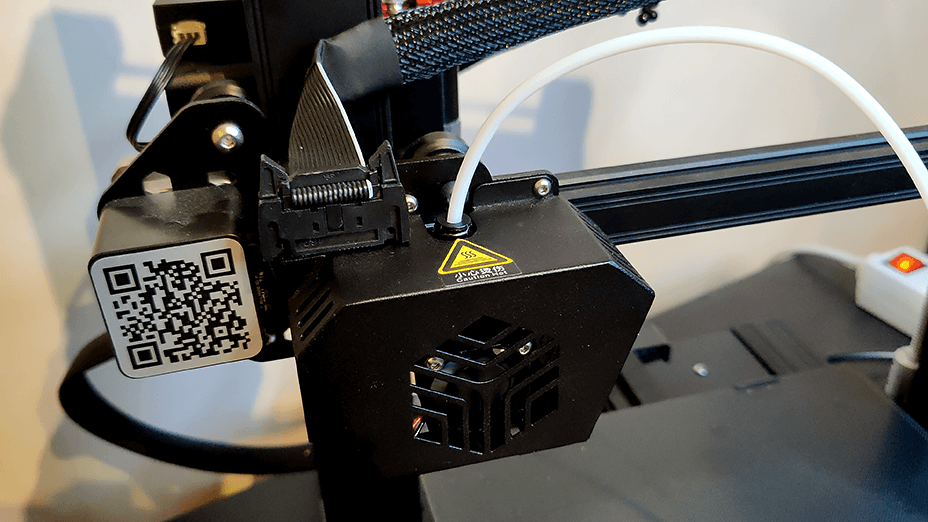

8. Insert short PTFE tube in the hotend.

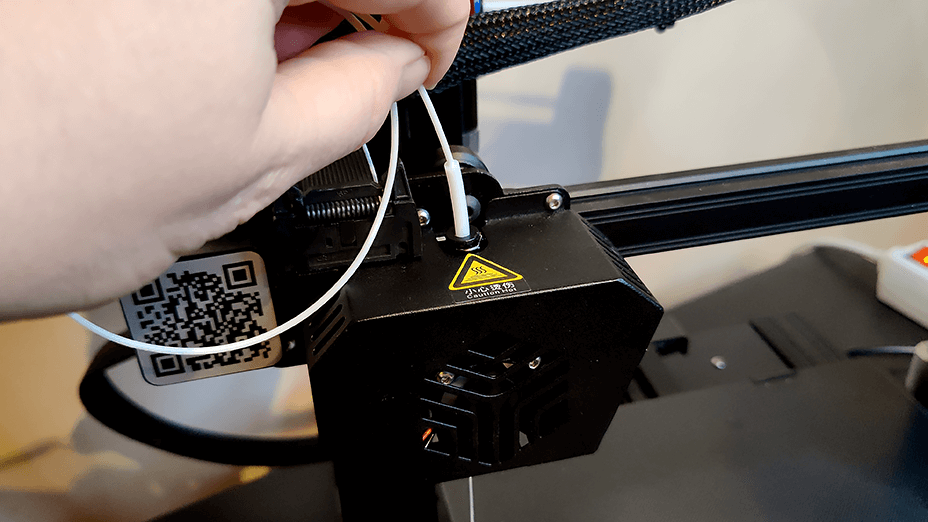

9. Use PLA filament to push it through the PTFE tube. The reason why i like to do the cold pull this way because it's easy to keep the pressure, and the tube guides the filament directly to nozzle.

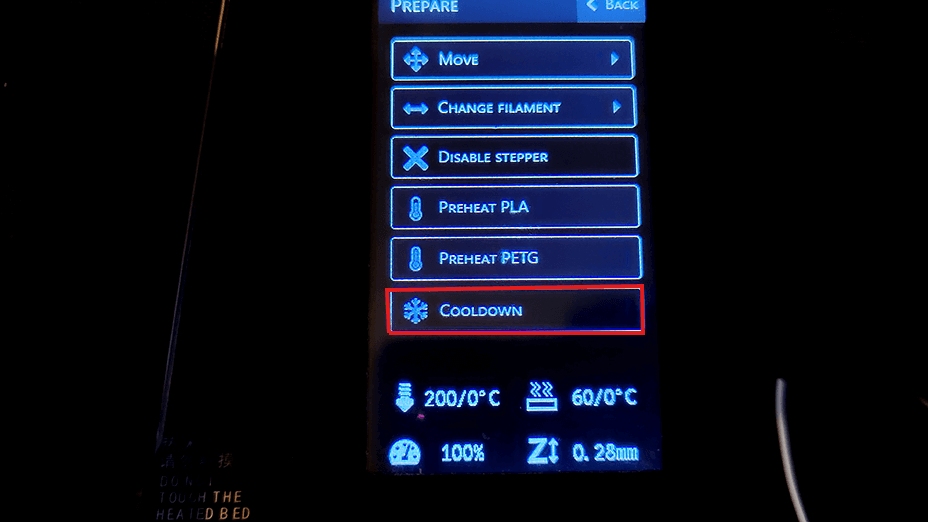

10. Keep pushing the filament and press cooldown button from your printer. You need to keep the pressure untill the hotend is cooled.

11. There is couple of ways to do the pull:

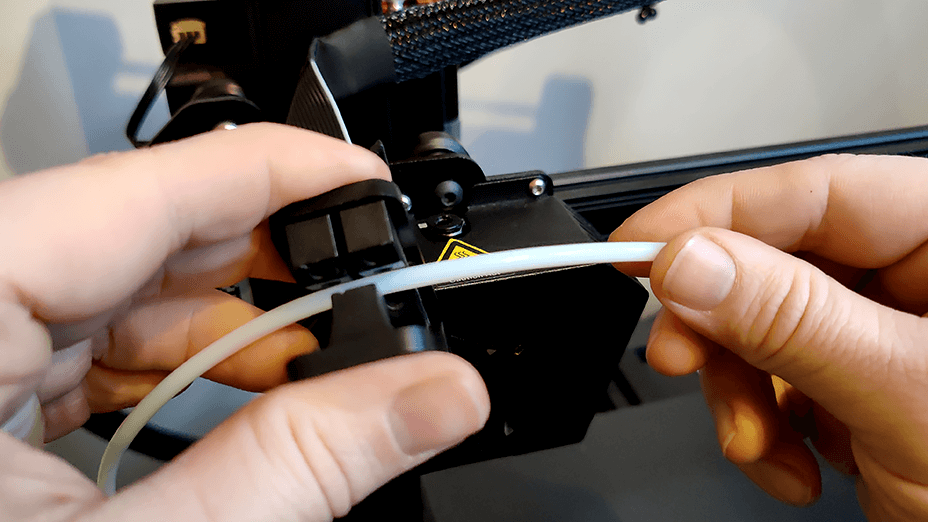

Option a. When your printer reaches 90°C (194°F) you pull the PTFE tube and PLA out at the same time.

Option b. When your printer reaches 60°C (140°F) you stop pushing. At this point some people let the nozzle to cooldown to room temperature before preheating it again. Now you can start the preheat again, and when your printer reaches 90°C (194°F) you pull the PTFE tube and PLA out at the same time.

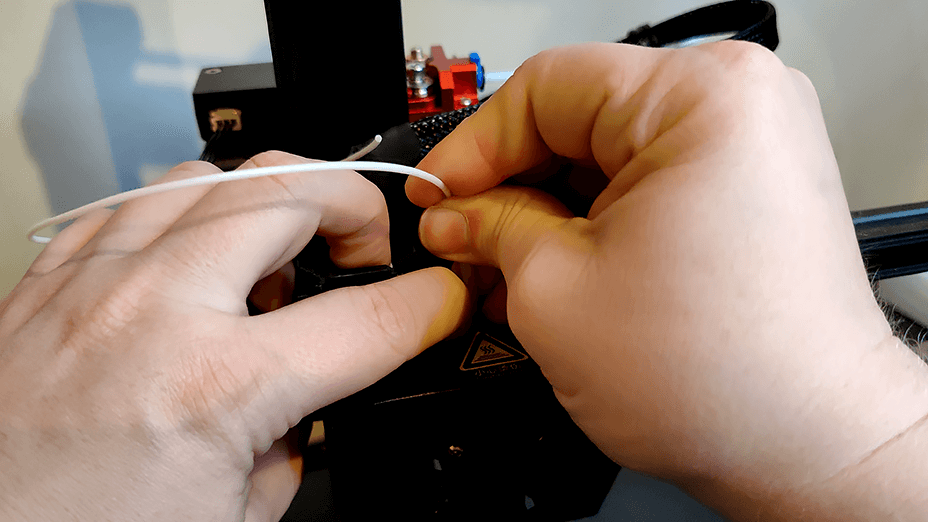

12. Cut the dirty part out and repeat the cold pull as many times you need.

0 Comments